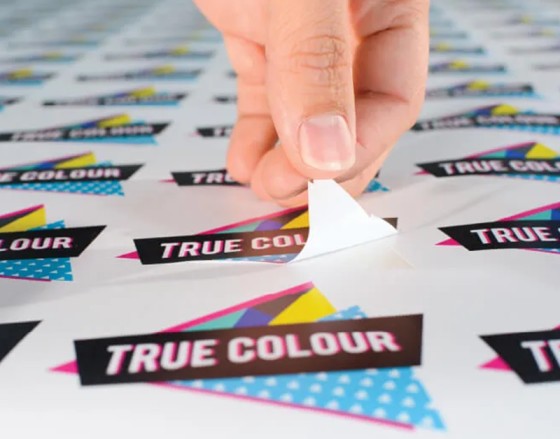

Why Vinyl Stickers Are the Gold Standard for Durability

Singapore’s climate creates real challenges for long-lasting labels. The mix of humidity, heat and unpredictable weather often causes ordinary stickers to peel, fade or wrinkle. This is why many businesses turn to vinyl stickers when they need materials that can withstand daily exposure without losing quality. Vinyl offers dependable strength, reliable adhesion and consistent performance in both indoor and outdoor environments. This article explores the features that make vinyl a trusted choice across industries, from waterproof layers to UV-resistant finishes that protect branding for the long term.

What Makes Vinyl Stickers Inherently Durable

Vinyl behaves differently from many other sticker materials because of its structure and resilience. These qualities play a central role in its durability and are the reason vinyl is suitable for so many demanding applications.

Vinyl is flexible yet strong, which means it resists tearing when applied on curved or irregular surfaces. Its composition also prevents shrinking, so the sticker keeps its original shape even when exposed to variations in temperature. This stability is especially important for labels placed on machinery, product packaging or vehicles where consistency and reliability matter.

Moisture resistance begins at the base PVC layer. Vinyl naturally repels water, so it does not swell or distort when exposed to condensation or accidental splashes. Combined with a robust adhesive that bonds well to glass, plastic, metal and coated paper, vinyl stays firmly in place for long-term use. These properties form the foundation for a sticker that is built to last.

As strong as this material is on its own, protective coatings enhance its resilience even further.

Waterproof Protection That Withstands Humidity and Rain

Businesses increasingly look for materials that can withstand moisture without losing clarity or adhesion. In a tropical climate, waterproofing is essential because wet conditions are a part of daily life.

Vinyl stickers are treated with protective layers that prevent ink from smudging or lifting when exposed to moisture. This keeps designs crisp even when used on cold bottles, cosmetic packaging or equipment that regularly encounters water. Waterproof coatings prevent bubbling or peeling that may happen when steam, rain or high humidity make contact with the surface.

Outdoor branding benefits greatly from this level of protection. Whether it is a label on a bicycle frame, signage placed along a storefront or tags used on outdoor packaging, vinyl maintains its appearance even after prolonged exposure to moisture. When businesses explore finishing options during sticker printing, waterproof performance is often at the top of their priority list.

Moisture protection forms only part of the long-term durability story. Sunlight exposure is another factor that dramatically affects sticker lifespan.

UV Resistance That Preserves Colour and Clarity

Sunlight can slowly fade or weaken many printed materials. For businesses placing stickers outdoors or near windows, UV resistance becomes essential to maintaining brand visibility.

Vinyl stickers can be laminated with UV-protective material that shields colours from fading. This helps printed artwork retain its vibrancy over long periods of time, even when constantly exposed to strong daylight. Brands use vinyl on vehicle decals, shopfront signage, outdoor promotional labels and equipment tags because it keeps colours looking sharp and readable.

This UV-resistant quality is also why many businesses prefer vinyl sticker printing in Singapore as part of their long-term branding strategy. It is reliable, consistent and capable of handling year-round sun exposure without losing its visual impact.

Sun protection works hand in hand with waterproofing and material strength, all of which prepare vinyl for both indoor and outdoor environments where performance matters.

Why Businesses Choose Vinyl for Indoor and Outdoor Use

Practical durability is often the deciding factor when choosing a sticker material. Vinyl offers consistent performance in conditions that would quickly damage weaker materials.

It handles temperature fluctuations without shrinking or warping. It remains smooth and clear even in humid environments, which is ideal for workplaces, kitchens and retail spaces. Its strong adhesion ensures that it stays securely fixed on vehicles, glass surfaces, packaging, laptops and machinery.

Businesses value vinyl because its long lifespan means fewer replacements and predictable results. For branding, consistency is important because labels often carry product information, safety instructions or promotional visuals that must remain visible at all times.

The wide range of applications highlights why vinyl continues to be a preferred choice for long-term labelling needs.

Stand Out With Reliable Long-Term Labels

Vinyl stickers in Singapore delivers dependable durability through its strong material base, waterproof coatings and UV-resistant layers. These qualities help businesses maintain clear and consistent branding across a wide range of surfaces and environments. Vinyl performs well in both indoor and outdoor settings, which makes it suitable for product packaging, signage, equipment tagging and promotional use. Its longevity ensures that colours stay vibrant and labels stay firmly in place.

If you want sticker solutions that remain reliable and visually appealing over time, consider working with a trusted provider. Reach out to Printsys to explore durable vinyl options tailored to your branding and labelling needs.

Frequently Asked Questions

1.Why are vinyl stickers preferred for Singapore’s climate?

They handle humidity, heat and rain without peeling or fading. Their waterproof and UV-resistant layers make them suitable for year-round outdoor use.

2. Are vinyl stickers really waterproof?

Yes. Vinyl naturally repels moisture and is paired with waterproof coatings that protect ink clarity, making it ideal for bottles, cosmetic packaging and outdoor applications.

3. Do vinyl stickers fade under sunlight?

Vinyl stickers can be laminated with UV-protective layers that prevent fading, helping colours stay vibrant even after prolonged exposure to strong Singapore sunlight.

4. What surfaces can vinyl stickers adhere to?

Vinyl bonds well to glass, plastic, metal, coated paper and smooth surfaces. The adhesive remains stable even in humid indoor spaces or outdoor environments.

5. Are vinyl stickers suitable for both indoor and outdoor branding?

Yes. They remain durable on product packaging, machinery, storefronts, vehicles, laptops and promotional displays, making them versatile for nearly any branding need.

6. Are vinyl stickers cost-effective for long-term use?

Although they cost slightly more than basic paper stickers, their durability reduces the need for frequent replacements—making them a cost-efficient choice over time.

5. What makes vinyl stickers stronger than other materials?

Their flexible PVC base resists tearing, shrinking and warping. Combined with strong adhesives and protective coatings, vinyl provides long-lasting stability.