The Art of Layering Transparent Stickers in Modern Packaging

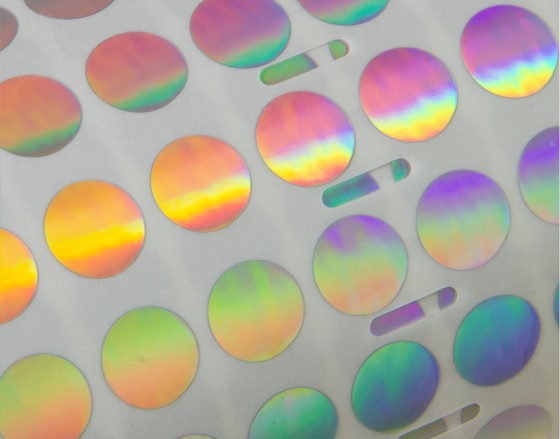

Layered transparency has become a standout design direction in the world of packaging. Brands are moving toward cleaner surfaces, subtle visual play and purposeful layering that guides attention. With the rise of transparent sticker printing in Singapore, designers now have far more creative room to experiment with clear materials that add depth without overwhelming the product. When layered with intention, transparent stickers can transform ordinary packaging into something visually engaging and modern.

Why Transparency Matters in Modern Packaging

Consumers today are drawn to packaging that feels clean and contemporary. Transparency supports this shift because it allows the product to be part of the design rather than something hidden behind solid labels. It creates space, reduces visual noise and gives the viewer a more honest first impression of what they are buying.

Clear surfaces can also feel more refined. Brands that prioritise minimalism often rely on transparent layers to reveal sections of the product while still controlling the visual story. This approach lets designers frame, accent or soften certain elements without introducing heavy colour blocks.

The way transparency behaves creates a natural base for more advanced visual techniques, which makes layered sticker design an appealing next step.

The Creative Power of Layering Transparent Stickers

Layering adds a three-dimensional quality that flat labels cannot produce. When designers use multiple transparent elements, each layer can hold its own purpose, such as illustration, text or pattern. The result is a composition that feels more dynamic while still remaining subtle.

Opacity is one of the most valuable tools in layered design. Instead of covering the product surface completely, designers work with partial coverage to establish hierarchy. Lightly opaque shapes can sit in the background, while sharper lines or colours placed above them guide attention naturally.

This effect becomes even more compelling when paired with professional transparent sticker printing. With precise cuts and consistent clarity, the layered components look intentionally aligned rather than assembled from mismatched parts.

Understanding the creative potential of layering sets the stage for exploring the techniques that make these effects stand out effectively.

Layering Techniques That Enhance Design Impact

Different design outcomes require different approaches, and layering transparent stickers gives designers a flexible toolkit. One approach uses transparency to frame key content. A lightly tinted clear sticker can act as a soft border around brand icons or ingredient callouts without visually boxing them in.

Foreground and background separation is another effective technique. Designers can place subtle shapes beneath a bolder top layer, creating a sense of depth that directs the viewer’s eye. This method works well for packaging that needs a sophisticated but approachable look.

Selective opacity is also useful. Keeping some areas crystal clear while others have slight tint helps create movement and emphasis. For instance, a clear circular window layered beneath a pattern might draw attention to a specific section of the product inside.

Some brands also use transparency to reveal small hints of what lies underneath. Instead of showing the entire product through one large window, layered elements can uncover only portions of it, which heightens curiosity and enhances storytelling.

These techniques work differently depending on the type of packaging the stickers are applied to, which makes material selection an important next consideration.

How Packaging Materials Influence Transparency Effects

The base material determines how each transparent layer ultimately appears. Clear containers naturally make a layered design more vivid since every applied element interacts with both the surface and the product underneath. Coloured or frosted packaging creates a more muted effect, which may enhance a brand’s aesthetic if they prefer subtlety.

Surface finish also matters. Glossy finishes produce sharper reflections which make transparent layers more pronounced. Matte finishes soften overlaps and create a more blended look. Textured materials change how light passes through each sticker and may make layered opacity gradients more noticeable.

Material compatibility is an important consideration for designers using transparent labels. Proper transparent sticker printing ensures that each layer retains clarity on various surfaces without bubbling or fading.

With the material context understood, the next factor affecting the final look is production quality.

Production Essentials for Professional Transparent Sticker Printing

Production is where design becomes reality, and layered transparent stickers require careful execution. Ink density is one of the most important elements since colours must remain crisp without appearing heavy on clear material. Too much density can create cloudiness, while too little results in washed-out visuals.

Adhesive clarity also shapes the quality of layering. A transparent sticker should blend into the packaging without visible borders. Clean cutting and uniform edges ensure that layers sit flush and do not distract from the intended design.

Preventing bubbling is essential. Even a small pocket of trapped air can distort the layered look. Quality printing processes help maintain clarity while keeping each sticker perfectly smooth.

This is where experienced providers in transparent sticker printing in Singapore become valuable because consistent output is crucial when graphics interact through multiple layers.

Strong production fundamentals allow layered stickers to perform well in real-world packaging settings, which is why many industries have adopted them.

Real-World Packaging Applications Using Layered Transparent Stickers

Many brands now use layered transparency as part of their identity. The cosmetics industry often applies clear labels to create clean and refined packaging. Layered transparent stickers let them highlight design accents without covering the product inside, making items like serums or creams more visually appealing on shelves.

Food and beverage packaging also benefits from this trend. Clear sections can reveal textures or colours of the product, which strengthens the consumer’s connection to freshness and quality. Layered elements can call attention to flavour descriptions or signature patterns without cluttering the container.

Lifestyle, stationery and gifting items often experiment with patterns layered over icons or illustrations. The stacked elements provide dimension while still keeping the packaging light and elegant. Professional transparent sticker printing in Singapore helps maintain clarity and crispness even across small decorative pieces.

These examples show how layered transparency turns packaging into a visually rich experience, which brings the discussion back to how brands can take action.

A Clear Advantage for Creative Packaging

Layered transparent stickers offer brands a powerful way to express identity through subtle detail, depth and refined composition. When combined with thoughtful placement and strong production quality, this approach can make packaging feel more distinctive and engaging.

For businesses ready to enhance their packaging with layered transparent designs, Printsys provides professional support backed by experience in high-quality sticker printing. Our expertise helps ensure clarity, precision and visual consistency across every layer. Connect with our team to explore how transparent sticker solutions can elevate your next project.

Frequently Asked Questions

1. Why is transparent sticker printing popular for packaging in Singapore?

Singapore consumers prefer clean, modern packaging. Transparent stickers allow designs to look refined while showcasing the product inside, enhancing trust and visual appeal.

2. How does layering improve transparent sticker design?

Layering adds depth and hierarchy. Designers can use opacity differences, framing, and foreground–background separation to guide attention and create a more dynamic layout.

3. What packaging types work best with layered transparent stickers?

Clear bottles, glass jars, glossy surfaces and smooth containers offer the strongest visual effect. Matte or frosted packaging produces softer, more subtle layered results.

4. Why is production quality so important for transparent stickers?

Transparent stickers reveal imperfections easily. High-quality printing prevents cloudiness, bubbling, opaque edges and colour inconsistencies that disrupt layered designs.

5. Which industries in Singapore use layered transparent stickers most?

Cosmetics, food and beverage, lifestyle goods and stationery brands commonly adopt this approach to create elegant, premium-looking packaging that stands out on shelves.